Our Products

- Common Rail. HEUI, EUI EUP test bench

- Diesel Fuel Injection Pump Test Bench

- Nozzle Tester

- PT Cummins Pump and Injector Test Bench

- Gasoline pump, gasoline nozzle, detector

- Electronically controlled diesel pump detector

- SPARE PARTS

- EUI/EUP TESTER/CAM BOX

- Common Rail Tester

- Common Rail/EUI/EUP/HEUI Tools

- Turbocharge

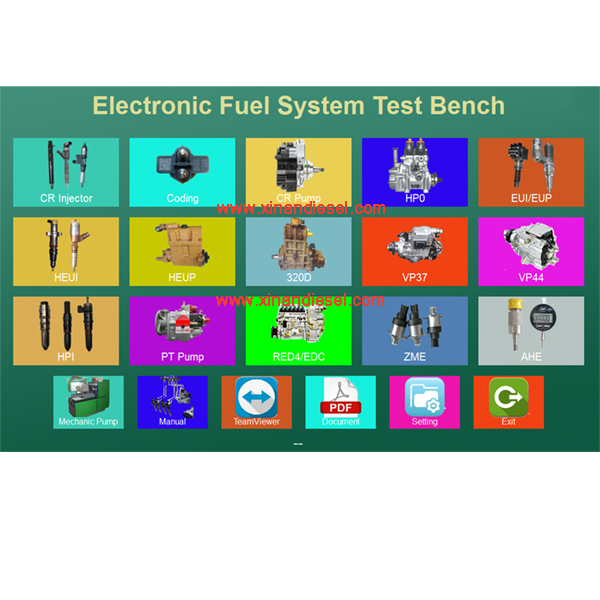

Common Rail. HEUI, EUI EUP test bench

NTS815A Common Rail Injector Pump Test Bench Diesel Fuel Injection Pump Test Bench

This NTS815A mainly test for common rail pump and injector, and diesel fuel injection pump(Mechnical Pumps)

1.Motor power:11KW, 15KW, 18.5KW, 22KW

2.Industrial PC with touch screen

3.Compressor cooling

4.Oil tank(including heating,refrigeration,liquid level detection,temperature detection)

5.Diesel tank(including heating,refrigeration,liquid level detection,temperature detection)

6.Flow meter detecting the fuel injection flow rate

7.Flow meter detection of common rail pump

8.Flow meter to detect oil flow

9.Flow meter detection of diesel oil return flow

10.B-OSCH common rail +DRV

11.Oil tank temperature sensor

12.Diesel fuel tank temperature sensor

13.Diesel supply temperature sensor

14.Diesel return temperature sensor

15.Oil pressure sensor

16.Diesel supply pressure sensor

17.Diesel return pressure sensor

18.Diesel pump internal pressure sensor

19.Oil pressure closed loop control module

20.The device is convenient to move and position the roller

21. Adjustable cylinders numbers: 12

22. RPM:0-4000

23. Support RPM Pre-set.

24. Temperature control system.

25. Positive Pressure System.

26. Negative Pressure System.

27. Air Supply

28. DC Power supply.

29. Internal Pressure of VE Pump

30. Oil return of VE Pump

31. Travel of Tooth Bar (Optional)

32. Oil Lubricate. (Optional)

33. Capability with Pump Type: All in-line and Rotary Pump .

NTS815A Common Rail Injector Pump Test Bench Diesel Fuel Injection Pump Test Bench Function:

Common Rail System Testing:

1.Test all the manufacturers of common rail injector

2.Test all the manufacturers of piezo injector

3.Test all the manufacturers of common rail pump

4.Test DENSO HP0 pump

5.Test CAT common rail (HEUI) injector

6.Test CAT common rail (HEUI) engine oil pump

7.Test CAT 320D common rail pump (the world's first successful development)

8.Test EUI/EUP (can adjust the lift but not to change the camshaft)

9.Test VP44 VE VP37 pump

10.Test RED3 RED4 TICS ZEXEL electronic control pump

11.Drive circuit board(solenold valve electric parameters to enhance the voltage

current,time,pull in voltage ,current,time,keep voltage ,current,time,according to the setting of parameters of production factory)

12.Accept the speed sensor ,encode signal,high speed solenoid valve drive signal.Accept the speed sensor ,encoder signal,

output 2 PWM drive signal, 2 way solenoid valve drive signal,1 high speed solenoid valve drive signal.

Driving signal waveform can be programed.

Diesel Fuel Injection Pump Testing Function:

1.Measurement of each cylinder delivery at any speed.

2. Test point and interval angle of oil supply of injection pump.

3. Checking and adjust the mechanical governor.

4. Checking and adjust the distributor pump.

5. Experiment and adjusting of behavior of supercharging and compensatory device.

6. Measurement of oil return of distributing pump.

7. Testing of the electromagnetic valve of distributor pump.(12V/24V)

8. Measurement of the internal pressure of distributor pump.

9. Checking the sealing of injection pump body.

10. Install tube of auto-sucking oil supply can check on oil supply pump (including VE Pump)

11. Checking the travel of stroke (Opitonal)

12. Oil lubricate (Optional)

13. Forced cooling system (Optional)

EUI / EUP Testing Function

HEUI Testing Function.